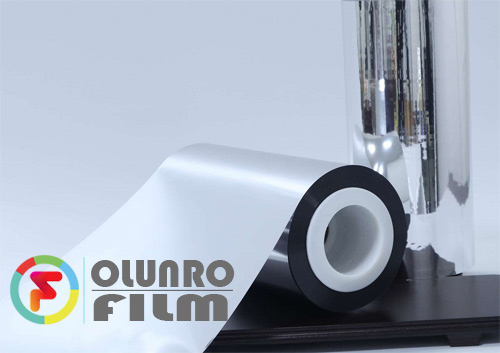

PE Metalized Film

Introduction to Our Innovative Packaging Solution: PE Metalized Film In the ever-evolving world of packaging, innovation and cost-efficiency are key drivers of success. At OLUNRO, we are committed to providing cutting-edge solutions that meet these demands. One of our most groundbreaking products is the PE Metalized Film, which can be laminated with BOPP or PET film to create a two-layer packaging structure. This innovative approach is designed to replace traditional three-layer structures, offering significant cost savings without compromising on quality or performance. The Advantages of PE Metalized Film Cost-Effective Solution One of the primary benefits of using PE Metalized Film in combination with BOPP or PET film is the potential for cost reduction. By eliminating the need for a third layer, manufacturers can achieve significant savings on materials and production costs. This streamlined structure not only reduces expenses but also simplifies the manufacturing process, leading to faster turnaround times and increased efficiency. Versatility and Compatibility Our PE Metalized Film is highly versatile and compatible with various types of packaging. It can be seamlessly laminated with both BOPP and PET films, making it suitable for a wide range of applications. From snacks and confectionery to household goods and beyond, this adaptable solution meets the needs of diverse industries. Sustainability and Environmental Impact [...]